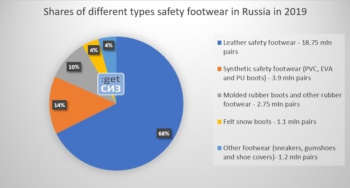

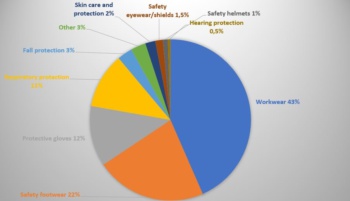

According to Getsiz.ru, the volume of the Russian safety footwear market (law enforcement agencies disregarded) including import, in 2019 amounted to 391 million Euros or 22% of the total PPE market (we estimate the total market to be 1.778 billion Euros).

The demand for the safety footwear reached 27.7 million pairs, 68% (or 18.75 million pairs) of which were made of leather.

The demand for the safety footwear reached 27.7 million pairs, 68% (or 18.75 million pairs) of which were made of leather.

In 2010-2017 the Russian safety footwear market grew at a high rate: on average by 10-12% annually. In 2018-2019 the growth rate fell to 4-6%. Reasons for the decline: PPE purchase budgets of large enterprises with state shares (that are now the main drivers of economic growth), are increasing by no more than 1-2% per year. The sanctions imposed on the Russian Federation are forcing the state-owned companies to cut costs. Russian manufacturers of safety footwear are trying to increase sales through the B2C market. Many safety footwear manufacturers: PTK «Moderam», «Avant-garde. Professional Outfitters», «Lel», «Paris Commune» and «Vakhrushi-Litobuv» cooperate closely with the online sales companies like Wildberries, «VseInstrumenty» and «Ozone». Some footwear manufacturers are actively entering the leasure and hiking footwear markets.

The introduction of mandatory footwear labeling with numeric codes in 2020 has also negatively affected the demand for footwear. And it does not just concern the safety footwear dealers who were not ready to carry out the labeling. For example, one of the leaders in online trading, Vseinstrumenty.ru, has removed safety footwear from its product range till the end of 2020 due to difficulties with the labeling.

Since 2014 the structure of the Russian safety footwear market has experienced significant changes. Over the past six years the share of imports has decreased by half: from 40% to 20%. Imports of safety footwear fell mainly due to the devaluation of the Russian ruble, which made it more profitable to produce footwear in Russia than to buy it abroad. Strengthened counterfeit control has resulted in a decrease of grey imports, which favorably affected the growth of domestic production. In addition, the Russian Government and the Ministry of Industry and Trade provide active support to local manufacturers of safety footwear both at the legislative and local levels in form of subsidies for the re-equipment of production facilities.

Since 2014 the structure of the Russian safety footwear market has experienced significant changes. Over the past six years the share of imports has decreased by half: from 40% to 20%. Imports of safety footwear fell mainly due to the devaluation of the Russian ruble, which made it more profitable to produce footwear in Russia than to buy it abroad. Strengthened counterfeit control has resulted in a decrease of grey imports, which favorably affected the growth of domestic production. In addition, the Russian Government and the Ministry of Industry and Trade provide active support to local manufacturers of safety footwear both at the legislative and local levels in form of subsidies for the re-equipment of production facilities.

The mandatory confirmation of Russian origin of safety footwear introduced by the Ministry of Industry and Trade for the suppliers of state-owned companies has also consolidated the positions of Russian manufacturers and increased their market share.

The Getsiz.ru rating is based on the official data (Ministry of Industry and Trade, Russian Statistics Agency, Russian Union of Tanners and Shoemakers, etc.), information from the companies themselves (financial reports and information provided at the request of our editorial board) and expert estimates in cases when manufacturers did not disclose information about production volumes. The top-20 chart covered leather safety footwear produced last year excluding footwear that was manufactured for the needs of the military and law enforcement agencies.

Companies designated as «Russian manufacturers of leather safety footwear» were to fulfill the following requirements:

- availability of own equipment for cutting and sewing uppers or using imported uppers;

- availability of own equipment for fixing soles by mechanical, chemical and/or combined method.

According to Getsiz.ru, the volume of the Russian safety footwear market (disregarding law enforcement agencies) including import in 2019 amounted to 391 million Euros or 22% of the total PPE market (we estimate it to be ca. 1.778 billion Euros). The demand for the safety footwear reached 27.7 million pairs, 68% (or 18.75 million pairs) of which were made of leather. The growth in the production of safety footwear made of synthetic materials outstriped the growth rate of leather safety footwear. Of the 18.75 million pairs leather footwear sold in Russia last year, about 63% (or 11.85 million pairs) was the footwear produced by the top-20 chart participants.

The geography of the manufacturers in the top-twenty list is very extensive and includes cities from Kaliningrad to Kirov, with most companies (four) registered in Moscow. Two companies are registered in each of the following regions and cities: Moscow region, St. Petersburg, Kirov, Kursk and Nizhny Novgorod. The Republic of Chuvashia, Kostroma, Tver, Kaliningrad and Penza regions are also present in the list. In other words the production of Russian safety footwear is decentralized.

The leader of the Russian top list, the Vostok-Service Group, produced 2.6 million pairs of leather safety footwear last year.

Top-20 Russian Manufacturers of Leather Safety Footwear (2019)

| № | Manufacturer | Region | Production volume in 2019, pairs | Changes in production volumes in 2019 compared to 2018 (%) |

| 1 | «Vostok-Service» Group | Moscow region | 2 600 000 | 5,2% |

| 2 | «ArtakObuv» ООО | Kostroma | 1 386 000 | 2,6% |

| 3 | «Technoavia Firm» PV OOO | Moscow | 1 150 000 | 2% |

| 4 | «PTK Moderam» AO | St. Petersburg | 984 000 | 2% |

| 5 | «Proizvodstvennaya Firma «Lel» OOO | Kirov region | 700 000 | No data available * |

| 6 | «Vakhrushi-Litobuv» OOO | Kirov region | 694 000 | 1% |

| 7 | «Yachting» OOO | Chuvashia | 640 000 | 3% |

| 8 | «Avangard Safety» Group | Bryansk region | 550 000 | 22,2% |

| 9 | «RASAA Firm» OOO | Kursk region | 400 000 | 4% |

| 10 | «Paritet» АО | Moscow region | 384 000 | 48,6% |

| 11 | «Legpromravitie Company» OOO | Moscow | 350 000 | No data available* |

| 12 | «MAG» OOO | Nizhny Novgorod | 350 000 | No data available* |

| 13 | «Kurskspetsobuv» OOO | Kursk region | 327 000 | 39% |

| 14 | «Spetszakaz» OOO | Penza region | 300 000 | No data available* |

| 15 | «Zapadbaltobuv» OOO | Kaliningrad region | 284 000 | No data available* |

| 16 | MOF «Paris Commune» ZAO | Moscow | 215 000 | No data available* |

| 17 | «Oskata’M» ООО | St. Petersburg | 165 000 | 5% |

| 18 | «Red Star» OOO | Tver region | 150 000 | No data available* |

| 19 | «LOK» ООО | Lipetsk region | 120 000 | No data available* |

| 20 | «Meridian» АО | Nizhny Novgorod | 102 000 | 8,5% |

| 11 851 000 |

* Production volume according to expert assessment

1. «Vostok-Service» Group (Noginsk, Moscow region)

«Vostok-Service» Group was founded in 1992. The Group produces safety footwear at two of its own production sites – «Torzhok Shoe Factory» ZAO (Torzhok, Tver region) and «Working Style» OOO (Uzlovaya, Tula region). Torzhok factory, which joined the Group in 2000, is the main footwear production site of «Vostok-Service».

Production facilities of Vostok-Service Group include eight injection molding machines Desma (Germany), which produce footwear with polyurethane (PU) soles, double polyurethane (PU/PU) soles, polyurethane with thermoplastic polyurethane sole laying (PU/TPU) and nitrile rubber sole laying (PU/rubber).

In 2019 Vostok-Service launched a new range of safety footwear «Uranium».

«Vostok-Service» Group among others delivers footwear to «Gazprom» PAO, «Severstal» PAO, «Rusal» OK, «MHK «Eurochem» AO and «Norilsk Nikel MMC» PAO.

In 2019 the company produced 2.6 million pairs of leather safety footwear (+ 5.2% compared to 2018). The company’s total annual revenue in 2019 according to Rosstat (Russian Statistics Agency) was ca. 237 million Euros.

Company’s website: www.vostok.ru

2. «ArtakObuv» ООО (Kostroma)

«ArtakObuv», founded in 2011, specializes in the manufacture of safety footwear of different price categories. The company has four injection molding units that allow producing footwear with two-component soles (PU/PU, PU/TPU and PU/rubber). The company sells its products mainly through a wide network of distributors.

«ArtakObuv» delivers footwear among others to «PO Sevmash» AO and MUPP «VMES».

In 2019 the company produced 1.386 million pairs of leather safety footwear (+2.6% compared to 2018).

Company’s website: костромаобувь.рф

3. «Firm «Technoavia» PV OOO (Moscow)

Technoavia Company was founded in 1992. The company incorporates Yoshkar-Ola Shoe Factory OJSC (Yoshkar-Ola), a full-cycle shoe production facility. The plant has four injection molding machines Desma. The equipment allows producing footwear with PU/PU, PU/TPU and PU/rubber soles.

Technoavia the only company in Russia that holds a license from W.L. Gore&Associates, Inc. to manufacture safety footwear using GORE-TEX® membrane. In 2020, a new range of safety footwear with GORE-TEX® membrane – «Captain Gore» — was launched.

Technoavia delivers footwear to RusHydro PAO, Lukoil-Energoseti OOO, Gazprom Georesource OOO, Norilsk Nickel MMC PAO, Vnukovo International Airport AO.

In 2019 the company produced 1.15 million pairs of leather safety footwear (+ 2% compared to 2018). By the end of the current year it is planned to increase output by 10%. The total revenue of the company in 2019 according to Rosstat amounted to ca. 186 million Euros.

Company’ website: www.technoavia.ru

4. «PTK Moderam» AO (St. Ptersburg)

Production and technologic company «Moderam» was founded in 1993. Footwear production is carried out in full cycle from cutting skin uppers to packaging of finished goods.

Most of the «Moderam» footwear has molded mount soles followed by hot vulcanization. Production facilities have five injection molding units from Desma (Germany) and Main Group (Italy) that allow producing shoes with PU, PU/TPU, PU/rubber and nitrile rubber soles. Both the intermediate and the outer layers of the soles are made on own production sites of «Moderam». The company also uses cemented shoe construction method making footwear with Vibram soles, as well as winter footwear with stitched on gumshoes with the ALPI folding spikes system.

In the production of footwear «Moderam» uses advanced technologies such as multi-layer insulation to protect against extreme cold and rubber soles with built-in metal spikes to prevent slipping on ice.

«Moderam» mainly produces footwear with leather uppers, but also of textiles: Cordura and microfiber: «Space Light» series. Textile uppers are made using 3D knitting technique. 3D knitting machines and equipment for laser cutting are installed at «Moderam» factory in St. Petersburg.

In 2019 «Moderam» launched a unique range of leather safety footwear with an autonomous heating system and anti-slip technology — the «Drive» and «Forward Buran» models. This footwear can be used at -50ºC.

In 2020 «Moderam» released a new collection of medical footwear.

«PTK» Moderam» delivers footwear to «Russian Post» FGUP, «Company «Vostsibugol» OOO, «GVSU №14» FGUP, «Sukhoi» Company PAO, «Inter RAO-Center Procurement Management» OOO, «Aeroflot» PAO, «RCC Progress» AO, «Transneft» PAO and Admiralty Shipyards AO.

In 2019 the company produced 984 thousand pairs of leather safety footwear (+ 2% compared to 2018) with a potential maximum capacity of 1.3 million pairs. According to Rosstat the total annual revenue of the company in 2019 amounted to ca. 14.288 million Euros.

Company’s website: www.moderam.ru

5. «Proizvodstvennaya Firma «Lel» ООО (Kirov)

«PF «Lel» LLC was founded in 1997. The company started producing safety footwear in 2006. In addition to safety footwear the company manufactures children’s and casual footwear. In the production injection molding machines are used, which can produce footwear with PU and PU/rubber soles under TM «ROVERBOOTS». «PF «Lel» cooperates with the largest Russian online store Wildberries.ru.

The company delivers footwear to «SIBECO» AO, «VSZ» PAO, «Admiralty Shipyards» AO, «IEMZ «Kupol» AO and «TGC-16» OAO.

In 2019 the company produced, according to experts, 700 thousand pairs of leather safety footwear. The total annual revenue of the company according to Rosstat amounted to 10.7 million Euros.

Company’s website: www.roverboots.ru

6. «Vahrushi-Litobuv» ООО (Kirov)

The company that dates back to 1854 is now a full-cycle enterprise. It is equipped with four Desma injection molding units, which allow the sole to be attached by three methods: molding, hot vulcanization and bead-stitching construction method.

In 2019 Vakhrush-Litobuv began providing customers with new services: audit and outsourcing of workwear, safety footwear and PPE.

Vakhrushi-Litobuv delivers its products to «Mosvodokanal» AO, «Rosvodokanal» Management Company OOO, «North-West» PAO, «Bashkiravtodor» OOO, RN-Tuapse Refinery LLC and «SIBEKO» JSC.

Vakhrushi-Litobuv delivers its products to «Mosvodokanal» JSC, «Rosvodokanal» Management Company LLC, «North-West» PJSC, «Bashkiravtodor» JSC, RN-Tuapse Refinery OOO and «SIBEKO» AO.

In 2019 the company launched a new range of lightweight nappa safety shoes with protective toe cap and perforated holes (model 501).

In 2019 the company produced 649 thousand pairs of leather safety footwear (+ 1% compared to 2018). By the end of 2020 the production is expected to increase by 5%. According to Rosstat the total annual revenue of the company amounted to 11.7 million Euros in 2019.

Company’s website: www.ooovlo.ru

7. «Yachting» ООО (Cheboksary)

«Yachting» OOO was founded in 1992. The company has full cycle production: from cutting uppers to attaching soles. The production is certified according to ISO 9001 and 14001.

The company has four Desma injection molding units, which allow producing safety footwear with all types of soles — PU, PU/PU, PU/TPU, polyurethane + two-layer thermo polyurethane (PU/TPU/TPU), PU/nitrile and single-layer rubber.

«Yachting» delivers safety footwear to Russian Railways, «Rosneft Oil Company» PAO, «ANK Bashneft» PAO, «Rostelecom» PAO, «Mechel» PAO, «Uralvagonzavod Research and Production Corporation» AO and «NPO Concern «Aurora» AO.

«Yachting» actively exports safety footwear to the former Soviet Union countries and beyond.

In 2019 the company produced 640 thousand pairs of leather safety footwear (+ 3% compared to 2018) with a potential maximum capacity of 1.1 million. The company’s total annual revenue in 2019 according to Rosstat was 4.346 million Euros.

Company’s website: www.yahting.biz

8. «Avant-garde. Professional Outfitters» Group (Moscow)

Footwear production facilities of the company are located in the township of Pogar, Bryansk region. The plant produces footwear in full cycle: from cutting leather to attaching soles. The company has three injection molding machines from Desma and Main Group, which produce safety footwear with PU/PU and PU/TPU soles.

«Avant-garde. Professional Outfitters» sells its product via own branches and a vast dealer network.

The Group of companies also delivers safety footwear under direct contracts to «NPO Mashinostroyenia», «ANK Bashneft» PAO, «Renaissance Construction» AO, «Crocus Group» AO and «RN-Moscow» AO.

In 2020 «Avant-garde. Professional Outfitters» has released a new range of safety footwear without metal parts called «Booster».

In 2019 the company produced 550 thousand pairs of leather safety footwear (+22% compared to 2018). In 2020 the production is planned to be increased to 750 thousand pairs. The total annual revenue of the company in 2019 according to Rosstat was about 21.523 million Euros.

Company’s website: www.avangard-sp.ru

9. «RASAA» ООО (Kusk)

«RASAA» LLC was set up in 1993. The company has two DESMA injection molding units, which produce footwear with PU and PU/TPU soles.

«RASAA» LLC delivers footwear to Russian Railways, «Mikhailovsky GOK» PAO and «Lebedinsky GOK» AO.

In 2019 the company produced 400 thousand pairs of leather safety footwear (+ 4% compared to 2018).

Company’s website: www.rasaa.ru

10. «Paritet»АО (Klin, Moscow region)

«Paritet» JSC is a full-cycle factory. It has four Desma and Main Group injection molding machines, producing footwear with PU/PU, PU/TPU and PU/rubber soles.

The main customers of «Paritet» AO are the Ministry of Defense and other uniformed agencies. In 2019 the company produced about 2.2 million pairs of footwear for the needs of the military and law enforcement agencies.

Among the civilian customers of «Paritet» are «Rostech», «Rosneft Oil Company» PAO, «Transneft» PAO and KamAZ PAO.

In 2019 the company produced 384 thousand pairs of leather safety footwear (+ 48.6% compared to 2018). The company’s total annual revenue according to Rosstat was 21.737 million Euros.

Company’s website: moskva-shtori.ru

11. «Legpromrazvitie» Company» ООО (Moscow)

«Legpromrazvitie» OOO is known as one of the largest manufacturers of workwear in Russia: the company occupies 18th place on the list of leading Russian distributors and manufacturers of PPE.

In 2008 «Legpromrazvitie» launched footwear production.

The plant has two Main Group (Italy) injection molding units.

«Legpromrazvitie» delivers safety footwear to «Rosneft Oil Company» PAO, «Lukoil» PAO, «Gazprom» PAO, «Transneft» PAO and «Rosenergoatom Concern» AO (Smolensk Nuclear Power Plant).

In 2019 the company produced 350 thousand pairs of leather safety footwear. The company’s total annual revenue according to Rosstat is 12.664 million Euros.

Company’s website: lprazvitie.ru

12. «MAG» ООО (Nizhny Novgorod)

The Nizhny Novgorod factory of occupational footwear «MAG» was founded in 2001.

The company is equipped with two injection units of Main Group (Italy) producing footwear with PU, PU/TPU and PU/rubber soles. Company’s products are sold both through dealers’ network and directly to consumers.

MAG OOO delivers safety footwear to Russian Railways, «Gazprom» PAO and «LUKOIL» PAO.

In 2019 MAG OOO, according to expert estimates, produced 350 thousand pairs of leather safety footwear.

Company’s website: magobuv.ru

13. «KurskSpetsObuv» OOO (Kursk)

«KurskSpetsObuv» has been producing safety footwear for over 10 years. The plant is equipped with two injection molding machines that produce footwear with PU, PU/PU, PU/TPU, PU/nitrile, PU/TPU/TPU soles.

«KurskSpetsObuv» sells its products through dealers’ network.

The company produced 327 thousand pairs of leather safety footwear in 2019 (+ 39% compared to 2018).

Company’s website: www.kurskspecobuv.ru

14. «Spetszakaz» ООО (Kuznetsk, Penza region)

The company was set up in 2006. It has two Desma injection molding machines producing safety footwear with PU, PU/TPU and PU/nitrile soles. «Spetszakaz» also produces footwear by lock-stitch cement and welt cement fastening methods of attaching soles.

«Spetszakaz» sells its products through a dealer network and large Russian distributors. The company’s main customers are «Spetsobyedinenie South-West» OOO, «TD «Tract» AO and «Komus».

In 2019 the company produced 300 thousand pairs of leather safety footwear with a potential maximum capacity of about 480 thousand pairs per year.

Company’s website: www.suraobuv.ru

15. «Zapadbaltobuv» ООO (Kaliningrad)

The company was founded in 2006. Production facilities of «Zapadbaltobuv» are located in Kaliningrad region. The plant has three injection molding units producing safety footwear with PU, PU/TPU and PU/nitrile soles.

The key customers of the company are large Russian distributor networks through which the main volume of products is sold. Directly «Zapadbaltobuv» delivers safety footwear to «Yantarenergo» AO and «Kaliningradteploset» MP.

In 2019 the company produced 284 thousand pairs of leather safety footwear. The company’s total annual revenue in 2019 according to Rosstat amounted to 5.282 million Euros.

Company’s website: www.zapadbaltobuv.ru

16. MOF «Paris Commune» ZAO (Moscow)

The «Paris Commune» Factory, one of the oldest Russian footwear enterprises, was founded in 1922. The company has five Desma injection molding machines producing footwear with PU/PU and PU/TPU soles. «Paris Commune» also manufactures heat-resistant safety footwear with nitrile rubber soles.

In the beginning of 2018 released a new range of safety footwear with improved customer properties called Full Guard.

The key customers of «Paris Commune» are «Surgutneftegaz» PAO and subsidiaries of «Gazprom» PAO.

MOF «Paris Commune» was one of the first companies to take part in the footwear marking experiment.

In 2019 the company produced 215 thousand pairs of leather safety footwear against 550 thousand pairs of military and children’s footwear, which account for the bulk of the company’s products. The production plan of safety footwear for 2020 is 400 thousand pairs.

The total revenue of the «Paris Commune» MOF ZAO in 2019 according to Rosstat amounted to 24.735 million Euros.

Company’s website: www.parcom.ru

17. «Oskata’M» ООО (St. Petersburg)

«Oskata’M» OOO was founded in 1996. The company’s production facilities are located in the Primorsky district of St. Petersburg. «Oskata’M» is a full-cycle plant.

Company has a Desma injection molding unit that can produce footwear with PU/PU, PU/TPU and PU/rubber soles. «Oskata’M» is one of the few plants in Russia that produces safety footwear using foamed thermo polyurethane technology.

The company delivers safety footwear to «MRSK Siberia» PAO, Petersburg Metro GUP, «OSK» AO, «Rosatom» State Corporation, «OTEK» AO, «PO Sevmash» AO, SPB GBUZ «Medsantrans», «PO Strela» AO and «Tupolev» PAO.

In 2019 the company produced 165 thousand pairs of leather safety footwear (+ 5% compared to 2018) with a potential maximum capacity of 360 thousand pairs per year. According to Rosstat the total annual revenue of the company in 2019 amounted to 1.241 million Euros.

Company’s website: www.oskata-spb.com

18. «Krasnaya Zvezda» (Red Star) OOO (Kimry, Tver region)

The shoe factory «Red Star» (formerly a factory of mechanical sewing of shoes «Anchor») was founded in 1907. This is one of the oldest Russian occupational and safety footwear. The factory manufactures footwear by injection molding, lock-stitch cement and vertical cement shoe construction methods.

The company, according to experts, produced in 2019 150 thousand pairs of leather safety footwear in 2019. The total annual revenue of the company in 2019 according to Rosstat amounted to 3.77 million Euros.

Company’s website: www.zvezdakimry.ru

19. «LOK» ООО (Lipetsk)

«LOK» OOO was founded in 2002. Lipetsk Shoe Company produces safety footwear with PU/TPU soles using Desma injection molding unit.

«LOK» OOO delivers footwear to «NLMK» PAO and Federal State Unitary Enterprise «State Corporation for Organization of Air Traffic in the Russian Federation».

In 2019 the company produced 120 thousand pairs of leather safety footwear.

Company’s website: www.lipok.ru

20. «Meridian»АО (Nizhny Novgorod)

«Meridian Group» AO is one of the leading garment manufacturers in Russia. It ranks 11th in the rating of domestic manufacturers of workwear and PPE according to 2019 statistics.

In 2013 Bogorodsk shoe factory (Bogorodsk, Nizhny Novgorod region) joined the group. For production of safety footwear Desma injection molding unit is used. It puts out footwear with PU and PU/TPU soles.

«Meridian» delivers safety footwear to «T-Plus» Holding, «Mineralnye Vody» International Airport OAO, «Yeniseyskaya TGK» AO (TGK-13) and «Inter RAO-Center Procurement Management Center of Inter RAO» OOO.

In 2019 the company produced 102 thousand pairs of leather safety footwear (+8.5% compared to 2018). The company’s total annual revenue in 2019 according to Rosstat was 20.779 million Euros.

Company’s website: www.meridian-workwear.com